More than

Facade technology

About SFT

Your partner for complex and sophisticated building envelopes

We plan aesthetic façades that can save energy for generations and deliver it at the same time.

We offer a comprehensive service that ranges from consulting to design, planning and tendering.

Services

You receive all building components from a single source and benefit from professional and efficient construction support. With our modular offer, you decide what you want and do without what you don't need.

-

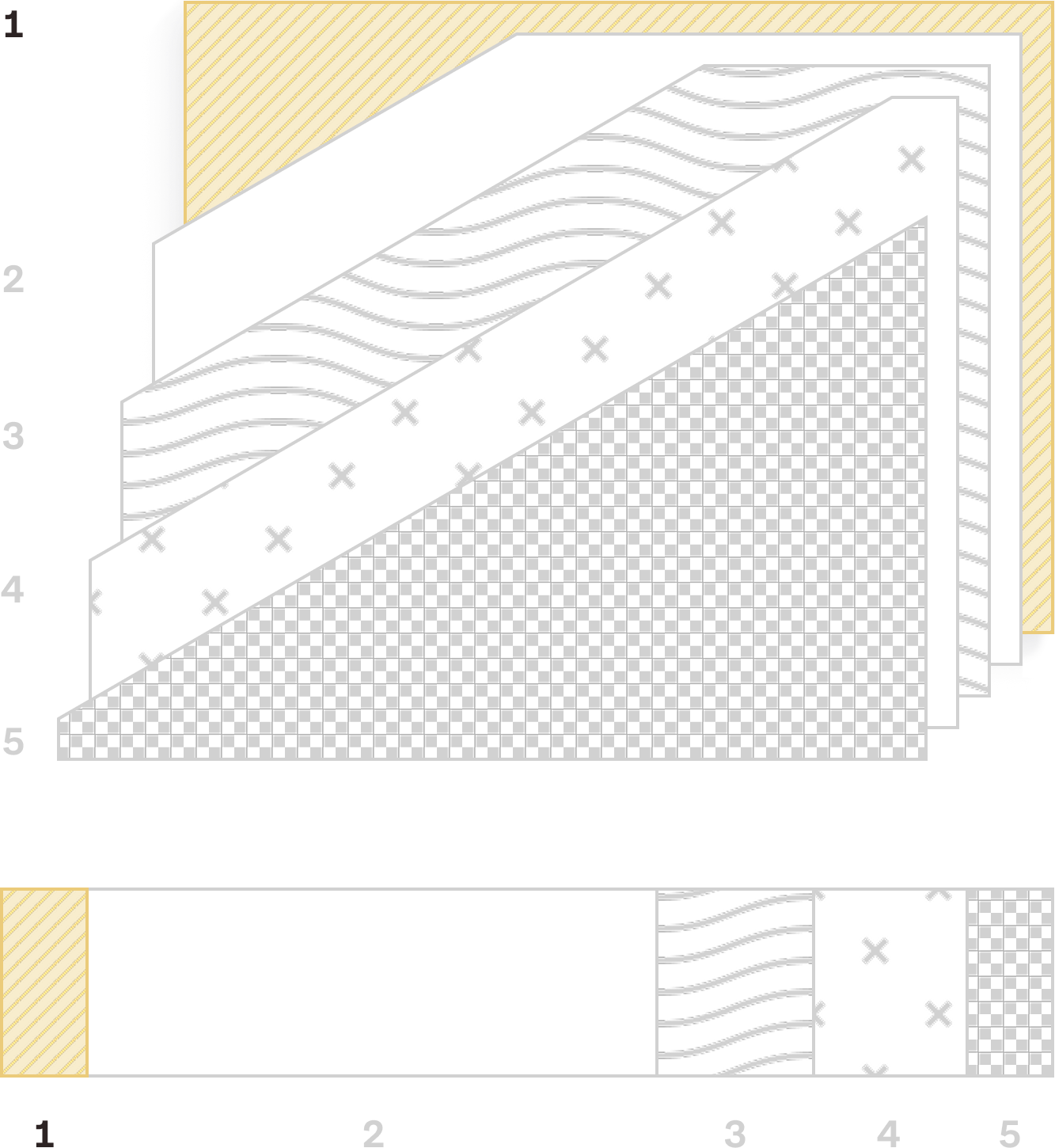

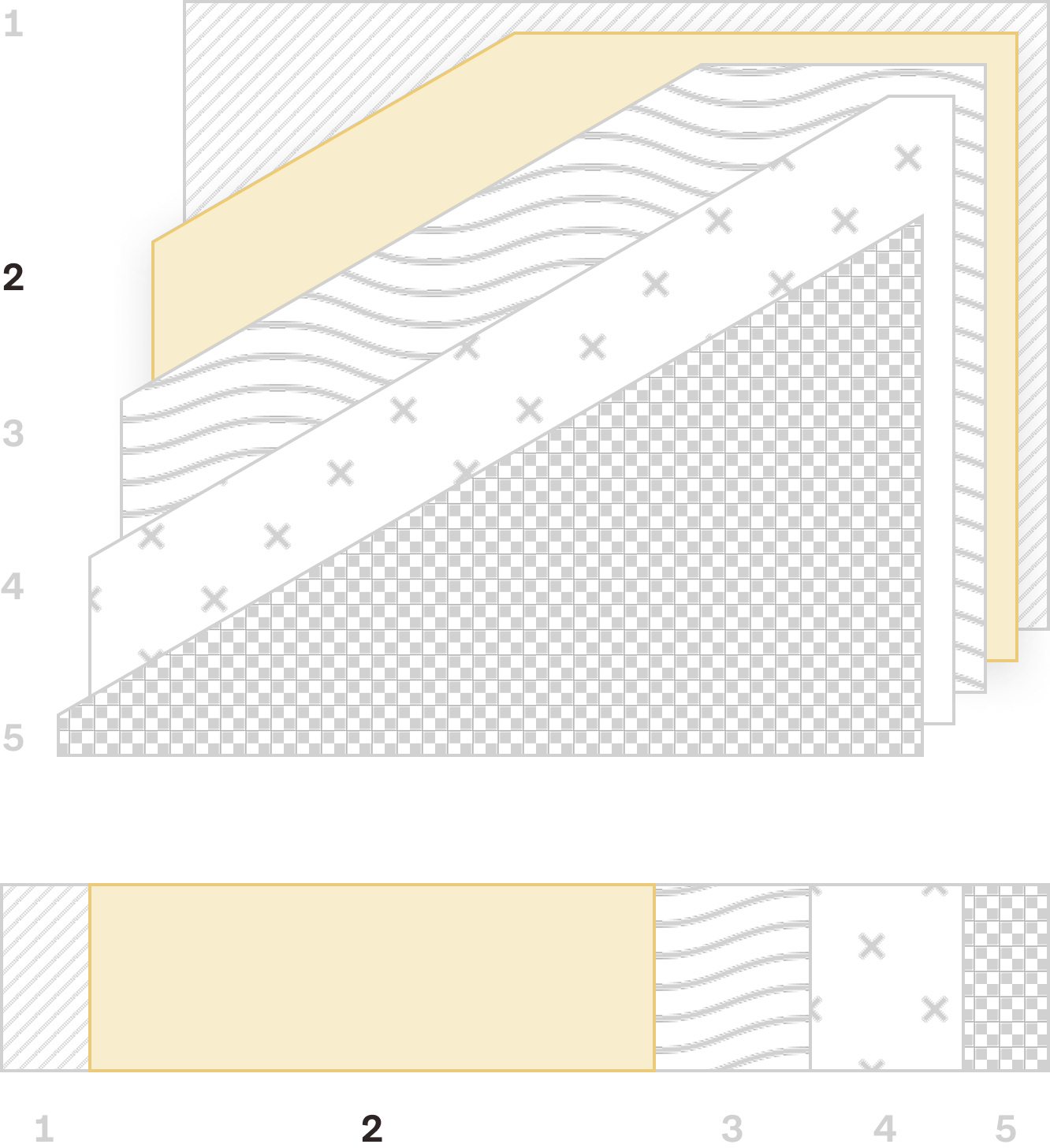

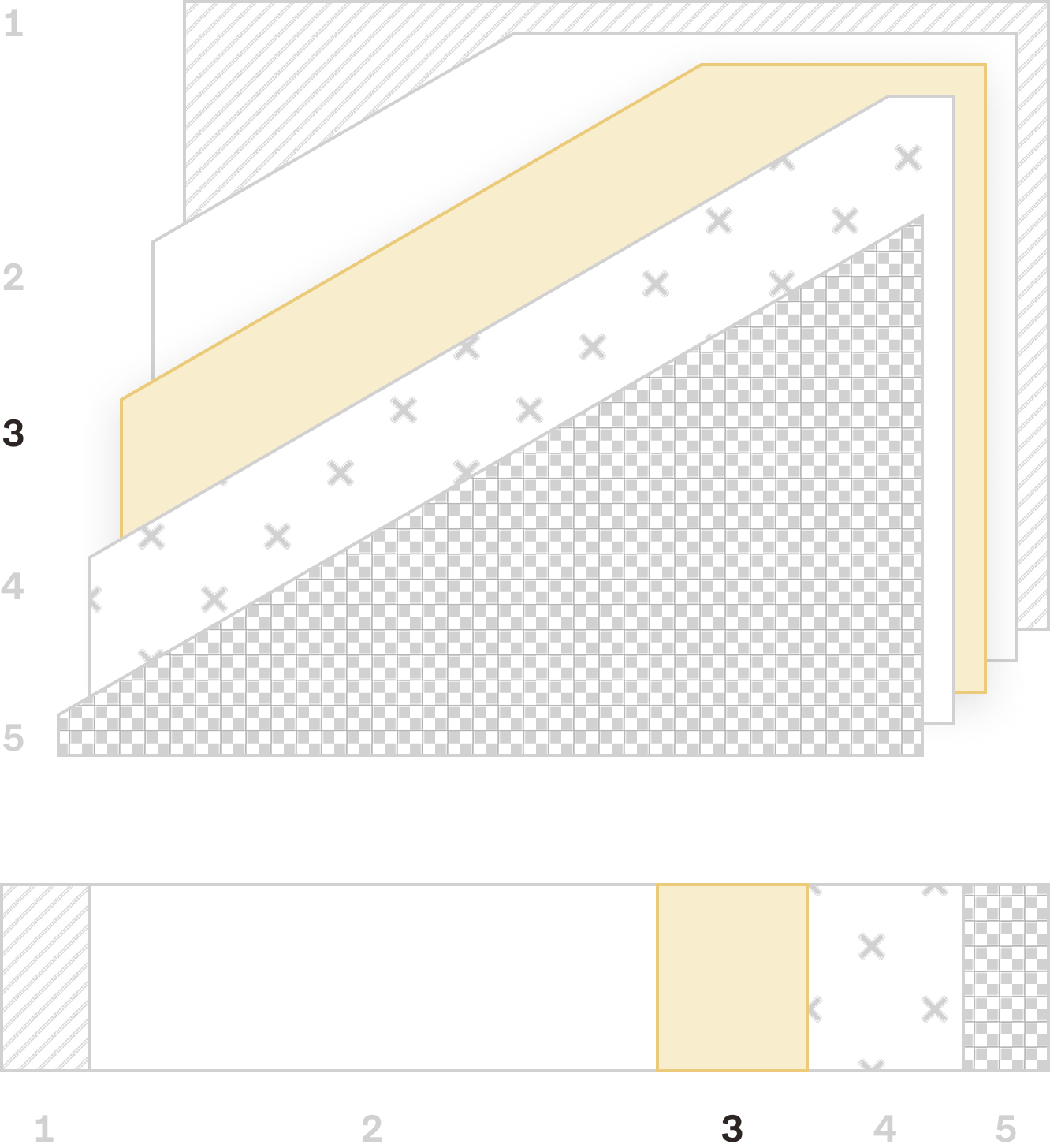

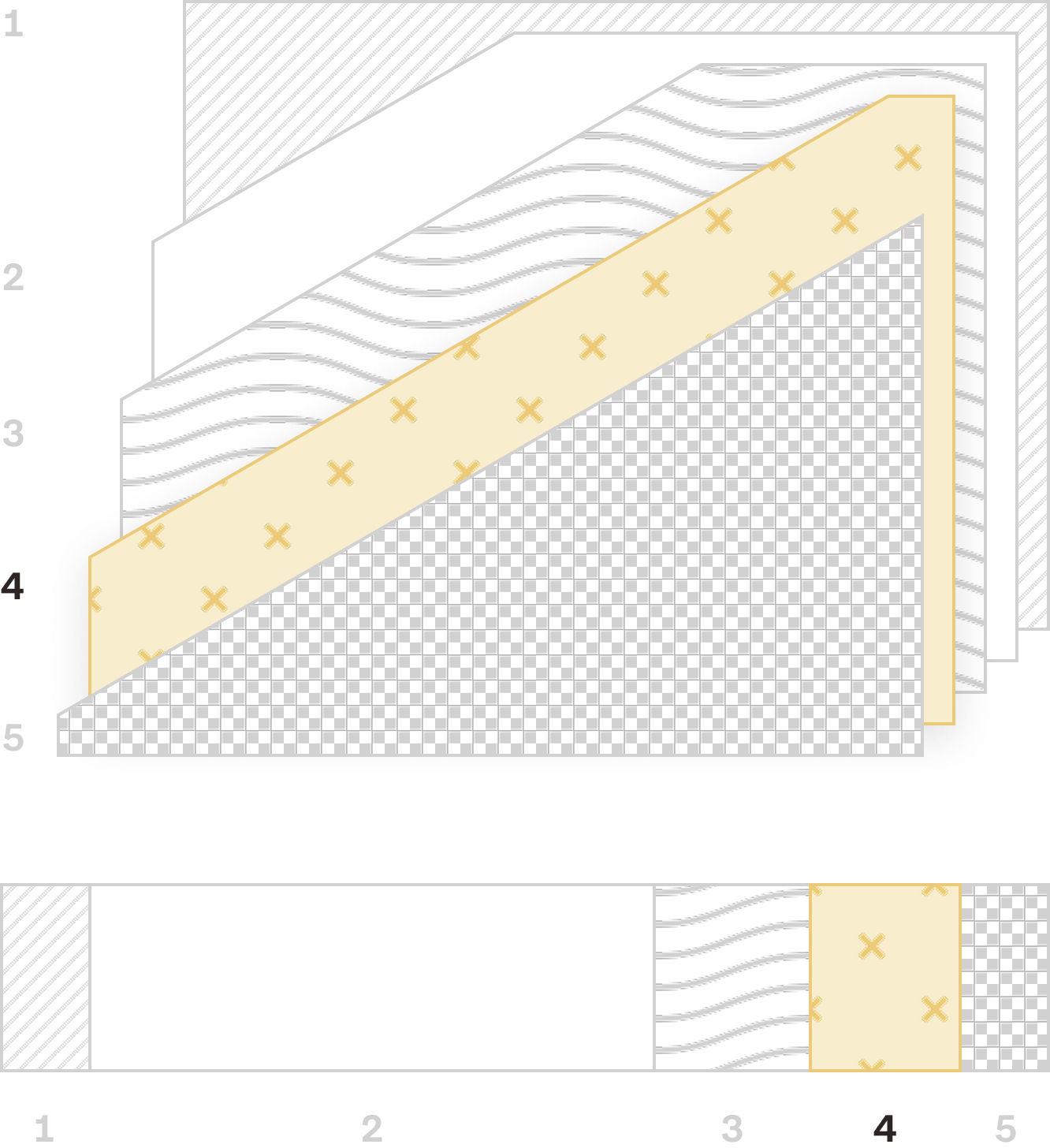

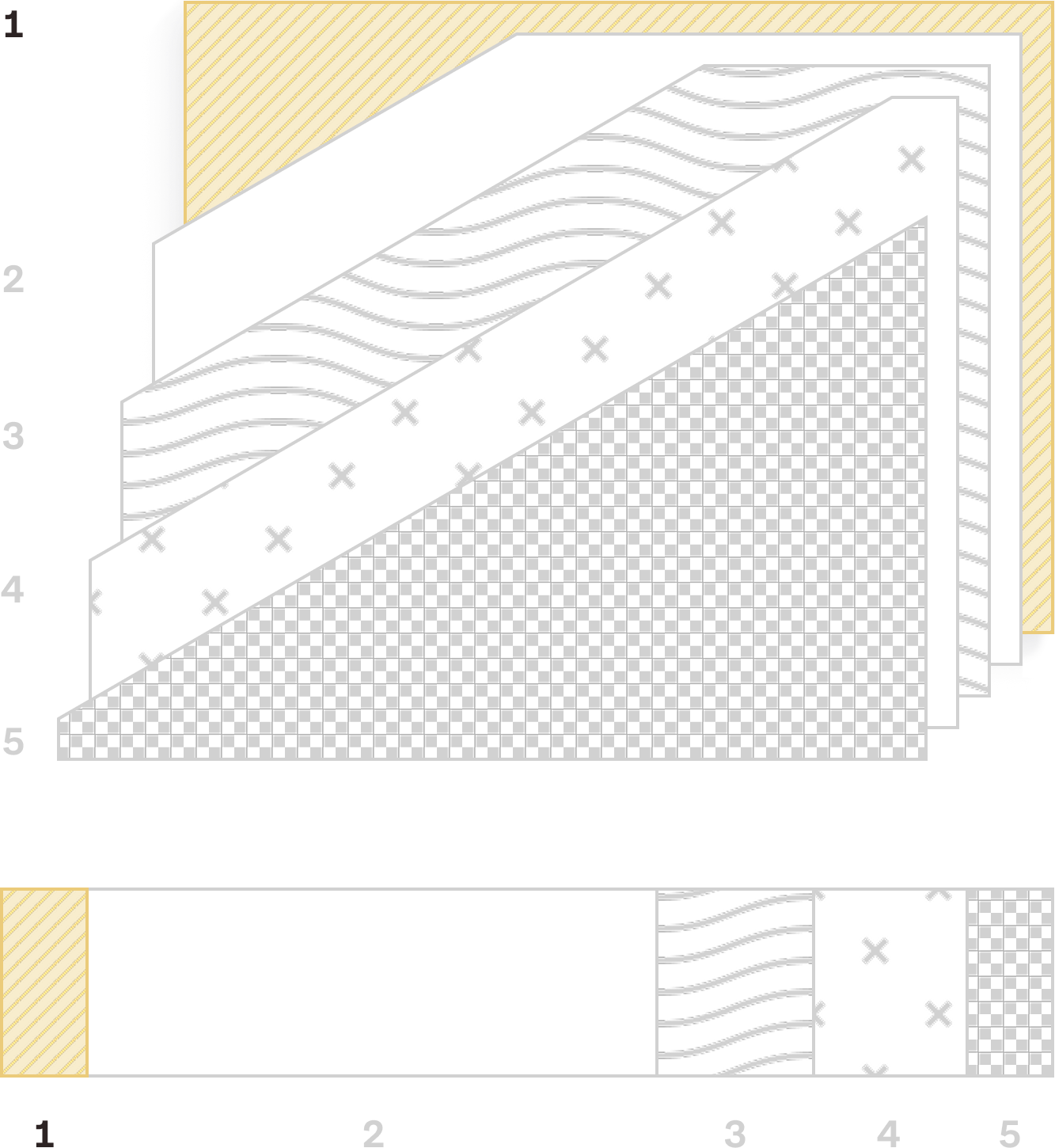

Primary substructure

The primary substructure of a rear-ventilated façade serves as a load-bearing base for the cladding and transfers its loads safely to the building structure. The construction must be weather-resistant, structurally stable and permanently anchored. Its exact design depends on the façade material and the building physics requirements.

As a specialist in rear-ventilated façades, we are familiar with the statics and thermal conductivity of the façade.

-

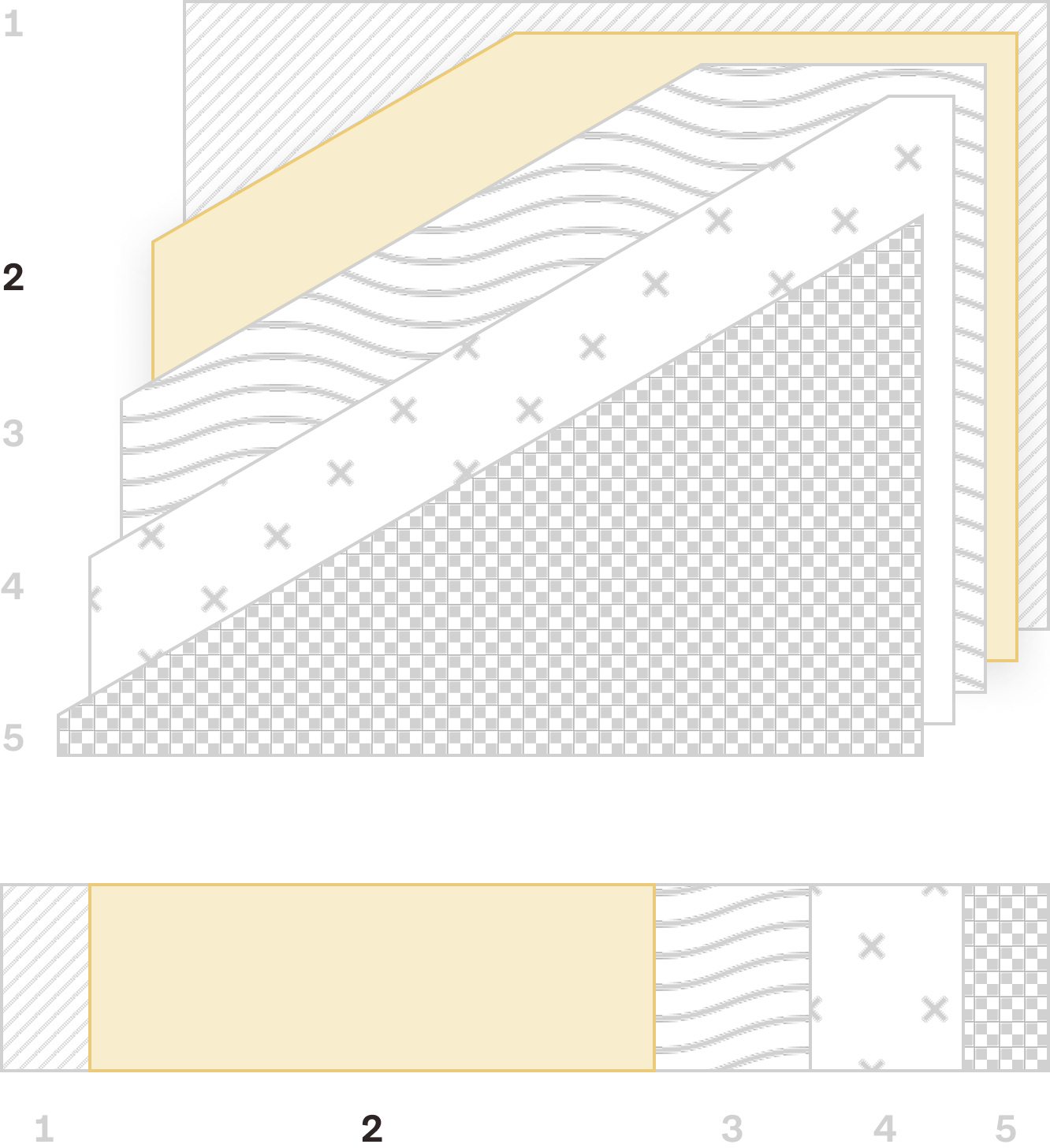

Thermal insulation

The thermal insulation in the rear-ventilated façade is installed between the load-bearing wall and the substructure. It serves to reduce heat loss and makes a significant contribution to the energy efficiency of the building. The insulation must be laid precisely and protected against moisture in order to guarantee its long-term function. The separation of insulation and weather protection keeps it dry and efficient.

-

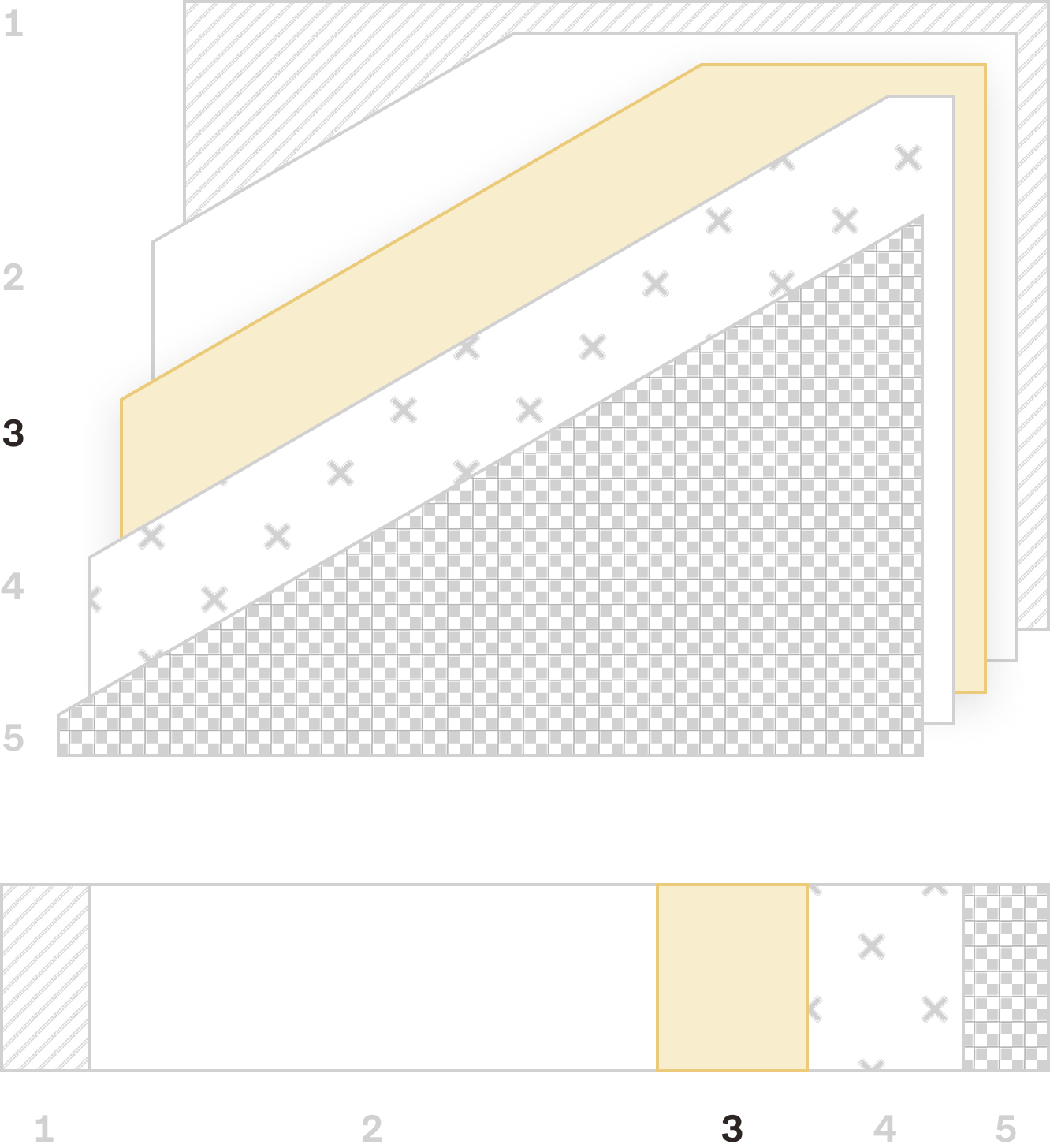

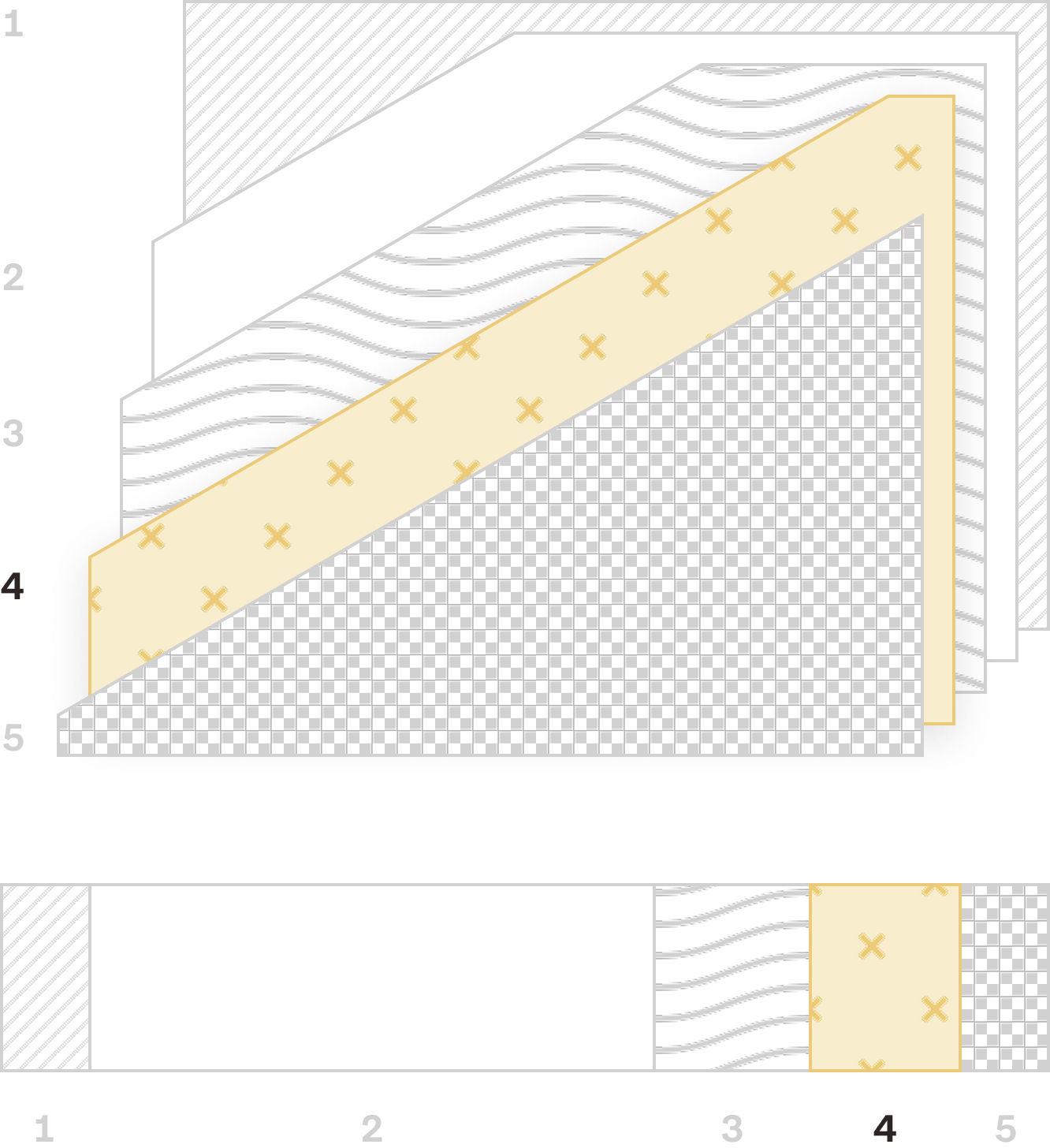

Secondary substructure

The secondary substructure of a ventilated façade connects the façade cladding to the primary supporting structure. It usually consists of horizontal or vertical profiles that are attached to the primary substructure. Their task is to hold the façade elements and allow the cladding to be precisely adjusted. The structure must be corrosion-resistant, dimensionally stable and adapted to the thermal movements of the façade.

-

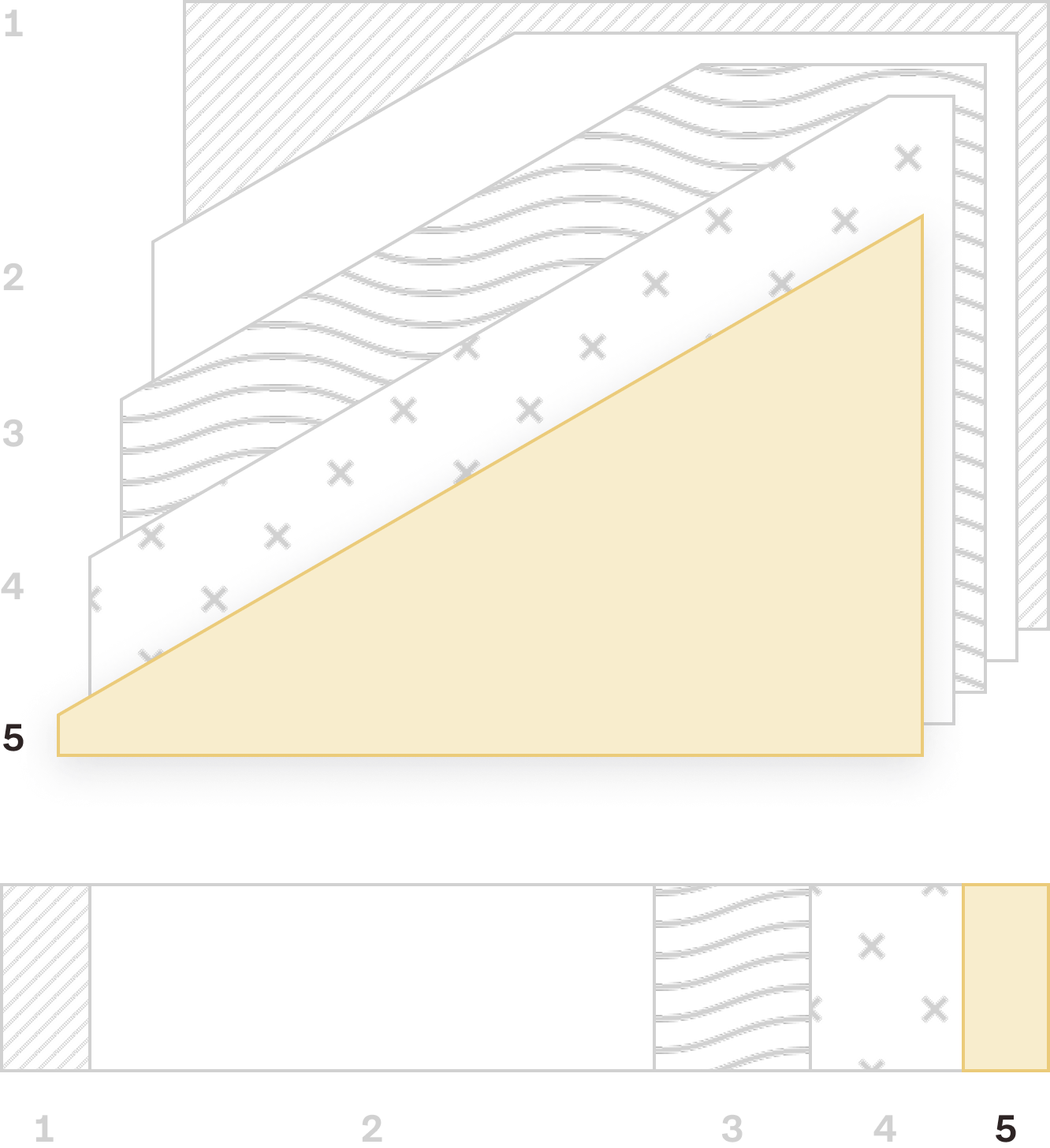

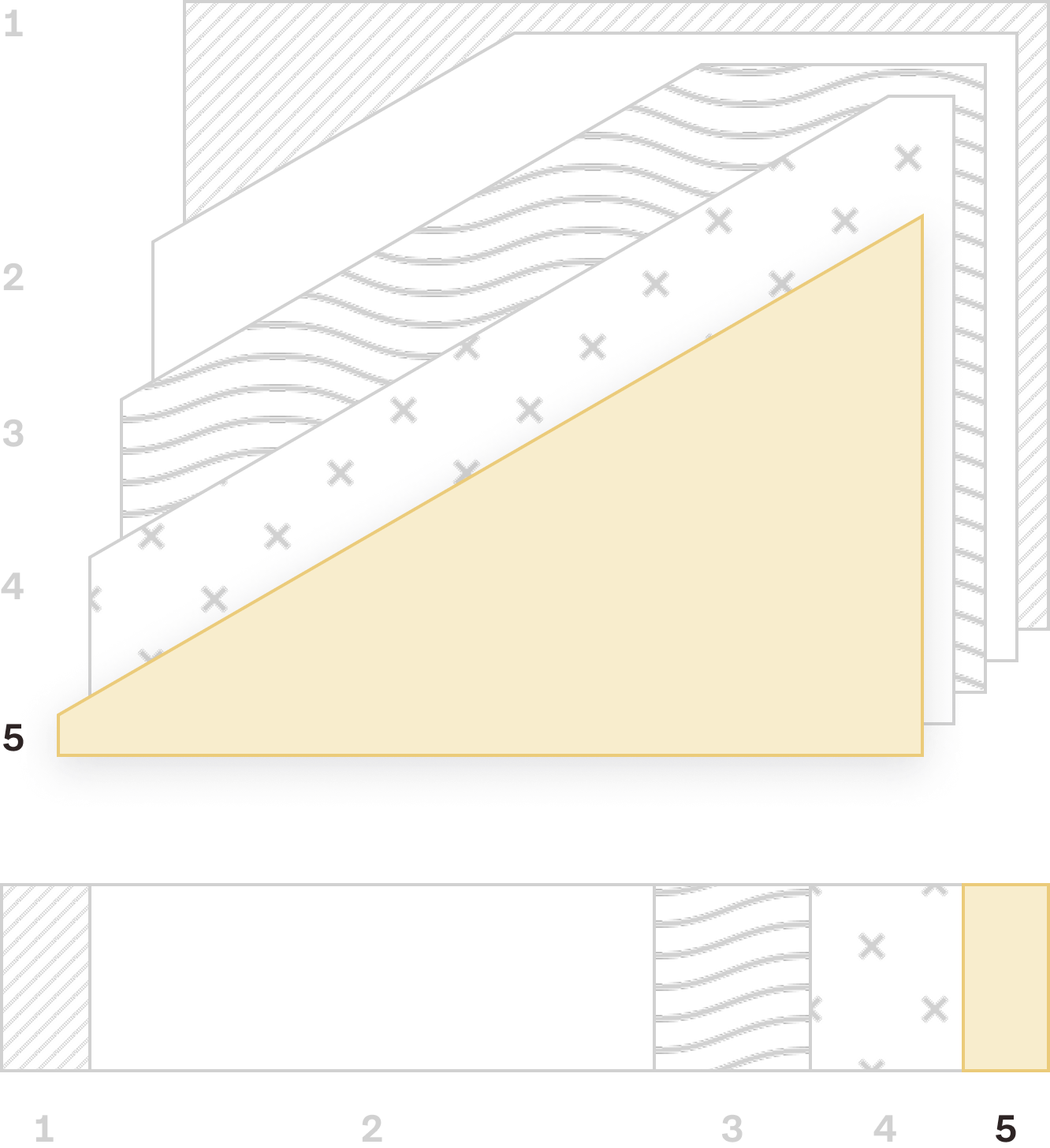

Building surface

The cladding of the building envelope on a rear-ventilated façade forms the visible, external finish of the façade system. It not only protects the building from weather influences such as rain, wind and UV radiation, it also fulfills an aesthetic and representative function in the façade design.

A wide variety of materials are used, such as fiber cement, ceramic, metal, glass or naturalstone - depending on the design and functional requirements. The cladding is mechanically attached to the substructure and leaves the rear ventilation gap free.

-

Metal components Building envelope

Metal components such as window frames, cover grilles and drip plates are important functional and design elements of the building envelope for ventilated façades. They ensure a clean finish at openings and transitions and at the same time protect against moisture penetration.

The components must be precisely manufactured and professionally installed so as not to impair rear ventilation or drainage. In addition to their protective function, they also contribute to the visual structure and enhancement of the façade.

Our approach

-

Feasibility check

- Analyse building shape and complexity

- Develop recommendation for VCF

-

Materialization

- Organize surface and façade samples

- Check material suitability for the desired application

- Show alternatives

-

Mockup

- Plan sampling according to defined size

- Organize sampling materials

- Coordinate construction

-

Advice on detailed solutions

- Create detailed solutions from hand sketch to execution planning

- Planning the façade from concept visualization to installation

- Support with fire protection

- Creating a fire protection concept from planning to inspection

-

Creating a project budget

- Creating a simple cost budget for the construction project

- Creating a detailed cost budget by dimension

-

Dimension VHF

- Creating a surface dimension

- Creating a detailed dimension for the tender SIA BKP 215, “ventilated façade”

-

Tender SIA NPK 215

- Preparation of the tender with or without dimensions

- Joint control of the tender with the client

- Handover of the tender and definition of the interfaces with other trades

-

Advice in the selection process

- Control of the submissions and the items entered

- Mandate to attend award meetings

-

PV façades

- Economic efficiency calculation of a PV façade

- Sampling of the PV modules

- Implementation planning of the PV façade incl. wiring

- Interface communication with electrical planner

Technical experts

We are your specialists for the construction and planning of a rear-ventilated façade. We are familiar with the construction, statics and choice of materials. We also have specialist planners for thermal insulation and fire protection as well as planners for metal façade components in our team.

-

30 years of ventilated façades

-

Solution-oriented doer

-

Managing Director

-

20 years of experience in the ventilated façade sector

-

Trained roofer & further training as a technical businessman

-

There's no such thing as impossible!

-

Project manager VSSM

-

Project management window and façade construction

-

Dipl. Techniker HF Bauplanung Architektur

-

Trained building plumber FZ in the building envelope

-

Cabinet maker EFZ & HFTG project manager structural engineering & glass fiber reinforced concrete element company

-

10 years of self-employment

-

From fitter to project manager

-

14 years of experience in the building envelope

-

Responsible order processing

-

Precision is his trademark

-

Foreman in roofing and tinsmith companies as well as head of technical service of a leading fiber cement manufacturer (location West-CH)

-

bilingual GER/FR

References